Options

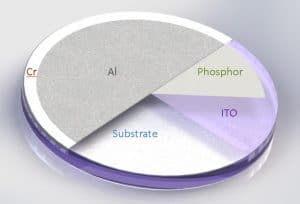

ITO underlayer

ProxiVision offers the conductive underlay coating of substrates with indium tin oxide (ITO) to reduce electrostatic effects on the screen caused by charged particles. Standard and special conductive parameters can be achieved.

To allow direct electric contact to a phosphor screen, a chromium ring of width up to 100 mm diameter can be sputtered on the outer area of the substrate. This is needed in the combination with ITO coating to reach position independent brightness of the screen fluorescence caused by charged particles.

Cr ring (diameter <100 mm)

To allow direct electric contact to a phosphor screen, a chromium ring of width up to 100 mm diameter can be sputtered on the outer area of the substrate. This is needed in the combination with ITO coating to reach position independent brightness of the screen fluorescence caused by charged particles.

Al reflection overlayer

To increase light efficiency by up to 100 %, it is advantageous for most applications to seal the phosphor coating with an aluminium layer on top of it. As a standard, a 40 nm to 50 nm coating is recommended, but on special request the thickness can be varied between 5 nm and 130 nm. The aluminium is a conductive overlay and cuts off light background in the system. The brightness is increased when used with electrons of more than 4 keV. In case of use with electrons below 4 keV no increase is achieved.

Water glass

To improve the mechanic stability of a phosphor screen, water glass can be added during the sedimentation process. A screen manufactured this way can resist a light finger touch. An efficiency decrease of 30% to 40% results from this manufacturing process as the density of the phosphor grains in the matrix is reduced.